詳細說明

Working principle of the gassing axis analysis

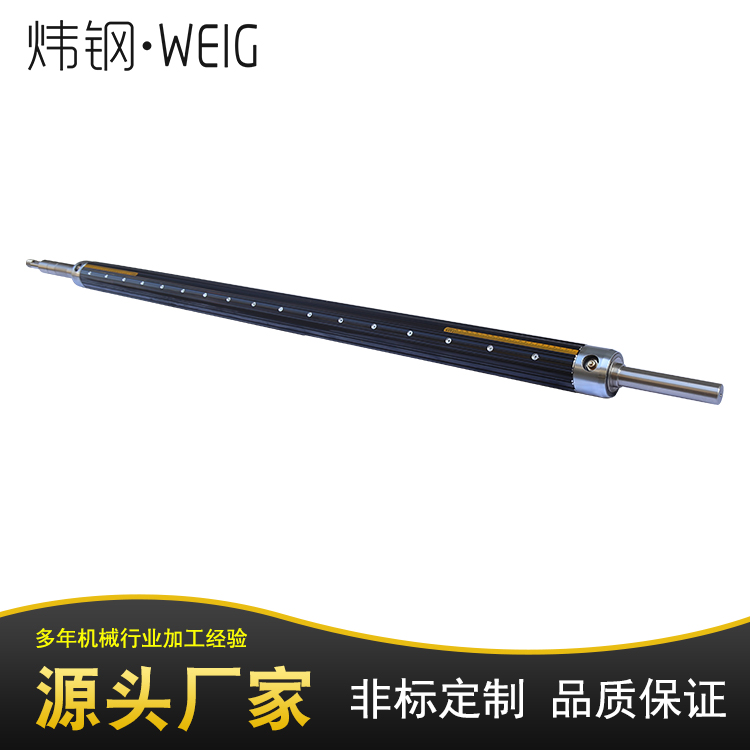

Principle of gassing axis: inflatable shaft is a kind of special winding, scroll, namely after high pressure air surface (refers to the key) can be raised axis, deflated after surface part of the article (key) quickly retracted gassing axis axis is called. It is the name of diversification, also called gas finale, expansion shaft, bilge gas shaft, inflatable roller, inflatable shaft, pressure shaft, inflatable roller, etc.

Called gassing axis is much, but the working principle of the same. Inflatable shaft, inflatable sets of use is very convenient, quick, just bring your own air supply, air pressure control in the range of 6 to 8 kg/cm2, need to lock the external components (such as a round tube), as long as the gas on the handle of the inflatable axis gas mouth filling can be completed, key article will highlight to resist external components (such as a round tube), the paper discharge to relaxation, with the hand to press the gas mouth sliding core gas deflated, article key to return to its original appearance, external components (such as a round tube) is desirable.

Classification of gassing axis: inflatable shaft is divided into bilge gassing axis key type, plate type, aluminum alloy inflatable gassing axis shaft and pneumatic nail axis, etc.

Inflatable shaft need to be aware of problems during installation

1. When making the installation of gassing axis, want to make sure that the first is to control the gas pressure of the compressor in a stable state, between the compressor and expansion shaft directly installed filters, prevent impurities clogging the trachea, resulting in leakage phenomenon;

2. Air into the direction should be vertical, in order to prevent damage to the valve;

3. The exhaust, must use the standard of form a complete set of vent, hammer, to ban the use of sharp tools, avoid to cause air leakage phenomenon;

4. To install the pressure gauge and pressure control device, and air pressure must be controlled in the range of 3 to 8 kg/cm;

5. Replace the gas nozzle, socket wrench must be used, if internal failure, need to remove the maintenance, should ask professional maintenance staff, don't be removed, in order to avoid unnecessary losses;

6. To handle with care to avoid injury to the valve.